Parking sensors, systems mounted on car bumpers that sense distance to nearby cars for parking Ground proximity warning system for aviation safety Vibration measurements of rotating shafts in machinery [5] Top dead centre (TDC)/camshaft sensor in reciprocating engines. Sheet break sensing in paper machine. Anti-aircraft warfare Roller coasters Conveyor systems Beverage and food can making lines[6] Improvised Explosive Devices or IEDs Mobile devices Touch screens that come in close proximity to the face[1] Attenuating radio power in close proximity to the body, in order to reduce radiation exposure[7] 3D Touch will come true with the aid of proximity sensing elements.[8] Automatic faucets

Type of Product :

Fiber Optic Sensor

Market in Brand :

Autonics, Papper+Fuchs, Ideal, Schneider, Wenglor, Omren, Leuze

A fiber optic sensor is a sensor that uses optical fiber either as the sensing element ("intrinsic sensors"), or as a means of relaying signals from a remote sensor to the electronics that process the signals ("extrinsic sensors"). Fibers have many uses in remote sensing. Depending on the application, fiber may be used because of its small size, or because no electrical power is needed at the remote location, or because many sensors can be multiplexed along the length of a fiber by using light wavelength shift for each sensor, or by sensing the time delay as light passes along the fiber through each sensor. Time delay can be determined using a device such as an optical time-domain reflectometer and wavelength shift can be calculated using an instrument implementing optical frequency domain reflectometry.

Fiber optic sensors are also immune to electromagnetic interference, and do not conduct electricity so they can be used in places where there is high voltage electricity or flammable material such as jet fuel. Fiber optic sensors can be designed to withstand high temperatures as well

Type of Product :

Photoelectric Sensor

Market in Brand :

Autonics, Papper+Fuchs, Ideal, Schneider, Wenglor, Omren, Leuze

A photoelectric sensor, or photo eye, is an equipment used to discover the distance, absence, or presence of an object by using a light transmitter, often infrared, and a photoelectric receiver. They are largely used in industrial manufacturing. There are three different useful types: opposed (through beam), retro-reflective, and proximity-sensing (diffused).

Type of Product :

Ultrasonic Sensor

Market in Brand :

Autonics, Papper+Fuchs, Ideal, Schneider, Wenglor, Omren, Leuze

Ultrasonic transducers are divided into three broad categories: transmitters, receivers and transceivers. Transmitters convert electrical signals into ultrasound, receivers convert ultrasound into electrical signals, and transceivers can both transmit and receive ultrasound.

In a similar way to radar and sonar, ultrasonic transducers are used in systems which evaluate targets by interpreting the reflected signals. For example, by measuring the time between sending a signal and receiving an echo the distance of an object can be calculated. Passive ultrasonic sensors are basically microphones that detect ultrasonic noise that is present under certain conditions.

Ultrasonic probes and ultrasonic baths apply ultrasonic energy to agitate particles in a wide range of materials; See Sonication.

Type of Product :

Rotary Encoder + Decoder

Market in Brand :

Autonics, Papper+Fuchs, Ideal, Schneider, Wenglor, Omren, Leuze

A rotary encoder, also called a shaft encoder, is an electro-mechanical device that converts the angular position or motion of a shaft or axle to an analog or digital signal.

There are two main types: absolute and incremental (relative). The output of absolute encoders indicates the current position of the shaft, making them angle transducers. The output of incremental encoders provides information about the motion of the shaft, which is typically further processed elsewhere into information such as speed, distance and position.

Rotary encoders are used in many applications that require precise shaft unlimited rotation—including industrial controls, robotics, special purpose photographic lenses,[1] computer input devices (such as optomechanical mice and trackballs), controlled stress rheometers, and rotating radar platforms.

Encoder technologies

Hall effect quadrature encoder, sensing gear teeth on the driveshaft of a robot vehicle.

- Conductive: A series of circumferential copper tracks etched onto a PCB is used to encode the information. Contact brushes sense the conductive areas. This form of encoder is now rarely seen except as a user input in digital multimeters.

- Optical: This uses a light shining onto a photodiode through slits in a metal or glass disc. Reflective versions also exist. This is one of the most common technologies. Optical encoders are very sensitive to dust.

- On-Axis Magnetic: This technology typically uses a specially magnetized 2 pole neodymium magnet the same size as the motor shaft that typically requires a custom motor shaft be used. The accuracy is very bad and does not allow many resolution options. This technology does not typically offer UVW or Z pulse outputs. Due to the 2 pole magnet there is lots of jitter on the output due to the internal interpolation.

- Off-Axis Magnetic: This technology typically employs the use of rubber bonded ferrite magnets attached to a metal hub. This offers flexibility in design and low cost for custom applications. Due to the flexibility in many off axis encoder chips they can be programmed to accept any number of pole widths so the chip can be placed in any position required for the application. Magnetic encoders operate in harsh environments where optical encoders would fail to work.

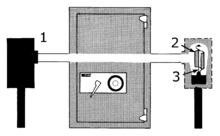

Type of Product :

Safety Switch

Market in Brand :

Autonics, Papper+Fuchs, Ideal, Schneider, Wenglor, Omren, Leuze

A safety switch is a device that quickly switches off the electricity supply if an electrical fault is detected, to minimise the risk of electricity-related fires, electric shock, injury and death.

By law, safety switches protecting power points and lighting circuits must be installed in all new homes and in buildings where electrical circuits are altered or added. This law was introduced in 1991, so if your home was built before this time, it may not be protected by safety switches.

Safety switches are also required for power outlets supplying caravans or similar accommodation in caravan parks.

If you are unsure whether your home has a safety switch, contact a licensed electrician for advice or to have one installed

Type of Product :

PressureTransmitter

Market in Brand :

Autonics, Papper+Fuchs, Ideal, Schneider, Wenglor, Omren, Leuze

A pressure transducer, often called a pressure transmitter, is a transducer that converts pressure into an analog electrical signal. Although there are various types of pressure transducers, one of the most common is the strain-gage basetransducer.

Type of Product :

Heat + Cool Transmiter

Market in Brand :

Autonics, Papper+Fuchs, Ideal, Schneider, Wenglor, Omren, Leuze

A temperature transmitter is a device that connects to a temperature sensor to transmit the signal elsewhere for monitoring and control purposes. Typically, thetemperature sensor is either an RTD, Thermisor or Thermocouple type sensorand will interface with a PLC, DCS, data logger or display hardware.

Type of Product :

Liquid Sensor

Market in Brand :

Autonics, Papper+Fuchs, Ideal, Schneider, Wenglor, Omren, Leuze

Level sensors detect the level of liquids and other fluids and fluidized solids, including slurries, granular materials, and powders that exhibit an upper free surface. Substances that flow become essentially horizontal in their containers (or other physical boundaries) because of gravity whereas most bulk solids pile at an angle of repose to a peak. The substance to be measured can be inside a container or can be in its natural form (e.g., a river or a lake). The level measurement can be either continuous or point values. Continuous level sensors measure level within a specified range and determine the exact amount of substance in a certain place, while point-level sensors only indicate whether the substance is above or below the sensing point. Generally the latter detect levels that are excessively high or low.

There are many physical and application variables that affect the selection of the optimal level monitoring method for industrial and commercial processes. The selection criteria include the physical: phase (liquid, solid or slurry), temperature, pressure or vacuum, chemistry, dielectric constant of medium, density (specific gravity) of medium, agitation (action), acoustical or electrical noise, vibration, mechanical shock, tank or bin size and shape. Also important are the application constraints: price, accuracy, appearance, response rate, ease of calibration or programming, physical size and mounting of the instrument, monitoring or control of continuous or discrete (point) levels. In short, level sensors are one of the very important sensors and play very important role in a variety of consumer/ industrial applications. As with other types of sensors, level sensors are available or can be designed using a variety of sensing principles. Selection of an appropriate type of sensor suiting to the application requirement is very important

Type of Product :

Vision Sensor

Market in Brand :

Autonics, Papper+Fuchs, Ideal, Schneider, Wenglor, Omren, Leuze

Vision sensors are very powerful in the sense that they can be used in various and flexible ways. For instance they can be used to display still or moving images from an external application or a plugin. Plugins can also provide customized image processing algorithms (e.g. filters) as well as evaluation algorithms (e.g. triggering conditions). There are several built-in filters that can be applied to images of a vision sensor. Refer to the filter composition section for more details.

Vision sensors can only render (and detect) renderable entities. Calculation results of vision sensors can be recorded by graph objects. Refer to graphs and graph data stream types for more information about how to record vision sensor data.

Type of Product :

Double Sheet Sensor

Market in Brand :

Autonics, Papper+Fuchs, Ideal, Schneider, Wenglor, Omren, Leuze

A device mounted at the front end of the feedboard of a sheetfed printing press, used to detect paper arriving early or late, a condition which would cause improper positioning of the image on the paper. A sheet detector can be one of four types:

A mechanical sheet detector identifies late sheets, and consists of a moving pin which, when a sheet arrives at the front guides of the feedboard at the proper time, is prevented from entering a hole at the bottom of the feedboard. When a sheet is late, the pin enters the hole, tripping the stoppage of the feeding mechanism.

An electromechanical sheet detector consists of a pair of open electrical contacts which are moved out of the way when paper arrives at the proper time. When the sheet is early, however, it hits the bottom contact, pushing it into the other contact. When the circuit is complete, the feeding action of the press stops.

A photoelectric sheet detector is timed to the front guides of the feedboard. One photoelectric cell is located beyond the front guides and detects early sheets. When an early sheet is not stopped by the front guides, it slides over the cell and causes an adjacent lamp to reflect into the cell, making an electrical contact and shutting off the feeder unit. A second photo cell located in front of the front guides has a lamp that turns on when the front guides are lowered. In normal printing operation, an on-time sheet reflects the light into the photo cell, initiating an electrical contact. When a sheet is late, there is no contact made, and the feeder unit shuts off.

A pneumatic sheet detector identifies sheets that arrive at the front guides crooked. A series of vacuum nozzles along the front guides is timed to the arrival of a sheet. Whenever there is a difference in air pressure between one set of nozzles and another (due to incorrect positioning of the sheet), the feeder mechanism is shut off.

All of the different types of sheet detectors can malfunction if not cleaned daily, and can be subject to wear due to abrasion from moving paper. They should be tested frequently. (See Feeder Section: Sheetfed Offset Lithography and Feedboard.) A different type of sheet detector, located earlier in the feeder section, detects more than one sheet being fed at once. (See Double-Sheet Detector.)

Get in Touch

Get in Touch